NEW CLICK HERE FOR THE AMAZON PRIME PAGES!

NEW CLICK HERE TO SEND US A GIFT! A COOL IDEA TO HELP US FOR HELPING YOU!

CLICK HERE FOR THE MAIN IOWA GOLD START PAGE

NEW IOWA GOLD FORUM WHERE TO GO, BUY SELL AND TRADE, EVENTS IN IOWA

NEW!! GOLD HOW TO PAGES HOW TO BUILD YOUR OWN GEAR!!

NEW BIG GOLD HOW TO PAGES FULL OF PLANS AND TIPS AND TRICKS OF HOW TO FIND GOLD

WHERE TO FIND GOLD IN THE USA A STATE BY STATE GUIDE

TECH SPECS ON GOLD WHAT IT IS ETC.

GOLD EQUIPMENT REVIEW GEAR WE HAVE TESTED AND WHAT WE THINK OF THE PRODUCT

DETECTOR PAGES GOLD AND COINS OR TRASH AND TREASURE TIPS AND TRICKS AND HOW TO PAGES

GOLD EQUIPMENT QUICK FIXES COOL TIPS HERE AND MORE ON HOW TO SET UP GEAR AND MORE TIPS AND TRICKS

IOWAGOLD NATURE AND TRAVEL PAGES!

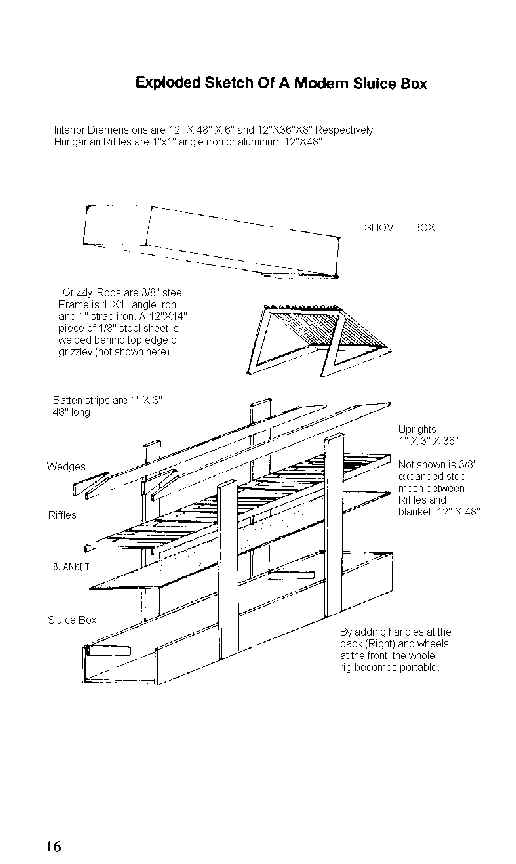

HOW TO BUILD A MODERN SLUICE / HIGHBANKER

This plant will wash 15 to 20 yards of material a day, with two men shoveling, and using a pump to supply water. If the ground is only yielding one pennyweight per yard, then it is possible to recover one ounce of gold a day. At today's market prices, that's not a bad return.

All of the sluice boxes in this design are 12" wide x 8" deep x 4 feet long. The shovel-in box is the same width and depth, but only three feet long. The bottom 'blanket' of indoor-outdoor carpet is 12" wide x 4 feet long, as is the expanded metal mesh. You can use 3/8" mesh in the bottom box and 1" mesh in the top box. This mesh is available at metals supply dealers in various sizes. However, one point to note is that mesh commonly supplied for plastering purposes has the incline of the mesh running crosswise. You need mesh with the incline running lengthwise. Be sure you get the right one.

Hungarian riffles

The Hungarian riffles aid in the breaking-up process, as materials pass over them and down the box, but they serve another important function. Every riffle creates a swirling action on its lower side, which helps the gold to separate and settle out of the lighter materials. The diamond mesh in the expanded metal screen also aids in this process, which is called 'cavitation'.If you watch carefully as the water is pouring down the sluice box; you will see a tiny whirlpool of water boiling in each diamond of the mesh. This is part of the cavitation process, and helps separate the gold from the other materials, to be captured in the fibers of the blanket on the bottom. In areas rich in coarser gold, the large one-inch mesh may be used to trap nuggets and flakes in the top box, while the finer 3/8 inch mesh in the Lower box or boxes traps the finer gold. Extremely fine flour gold requires a greater Length of box and slower moving water in order to permit it to settle. Indeed, the water of the North Saskatchewan, which contains much fine gold in its gravel, is reputed to be greasy. And we have seen flour gold there so fine that it was floating on lop of the water, in the pan, trapped, perhaps by either grease in the water, or surface tension.

How the Hungarian Riffle

Works.

How the Hungarian Riffle

Works.

The water swirls behind each of the riffles, depositing fines.

The Hungarian riffles are made from 24 pieces of "angle iron, 11 5/8" long, welded with the back edges 2" apart between 48" lengths of 1" strap iron. The angles of the riffles should all face the same way, so that the flanges of the iron point 'downstream' when installed in the box. You can cut 1" angle and strap iron with an ordinary hack saw, but you need your friendly local welder or welding shop to weld them to the strap iron. If you don't have access to angle iron or a welder, you can make your riffles from 1'' x 3/4', lumber, and nail 1" strap iron along the top edges of the 3/4'' dimension. This will give you a 1/4" overhang on the 'downstream' side to create the swirling action. The outside dimension of the wooden riffles should be perhaps not more than II 3/4 inches wide, to allow for swelling of the wood when it becomes soaking wet. The old timers used strap iron, as they had no welders, but we prefer modern angle iron, as it is easier to clean and doesn't swell when wet.

The Grizzly The grizzly is an important part of a sluice box, as it separates the finer materials from the larger rocks and pebbles, permitting more efficient gold separation. It is installed from the end of the shovel-inbox down to the end of the first sluice box, at a 45 degree angle. The sand and gravel mixed with water in the shovel-in box pour over the grizzly, and the finer materials drop into the sluice box, while the coarser materials roll off onto the dump. A piece of sheet metal 12" wide x 14" deep is welded along its top edge behind the top of the grizzly bars. Its bottom edge is pulled out about two inches from the grizzly bars. This 'splash plate' helps to slow down the rush of water to gravity feed rate, and it prevents a cascade of materials from interfering with the efficient cavitation action in the top end of the box.The grizzly is made from 12 pieces of 3/8" steel rod, each 12 inches long. Place two 12" long pieces of the I" flat iron flat on the welding bench 12" apart, arid weld the rods between them, starting at one side, and spacing the rods alternately 3/8" and 1/2" apart. The 12" x 14" piece of sheet metal is welded along the strap iron at one end and the other end is pulled out about 2" to serve as a splash plate. The grizzly is then installed with the rods in a vertical position, and only materials smaller than 1/2" may pass through it.

Water Supply

You can supply water to any of these boxes by pouring it in with a bucket. This is kind of slow going. Or you can pipe water in from a dam or a neighboring stream situated uphill from your plant. The handiest way is to use a five horsepower centrifugal pump, available from construction equipment dealers. Powered by a gasoline motor, usually a Briggs and Stratton, this pump will easily deliver 90 gallons of water a minute all day, without straining, using 11/2" fire hose. It is particularly useful if you are some distance up the bank from a creek, as you can set your pump on the creek bank and just take the hose up to where you want to work.The nozzle of your hose is clamped onto a crosspiece across the bottom end of your shovel-in box, with the flow of water directed up the box, to thoroughly mix up, break down and liquefy the materials you are shovelling in.

With your sluice box setup and ready to operate, you startup your pump and the water starts flowing into the shovel-in box. Then you simply start shovelling in the material. It is important not to have the water flowing too fast through your washing plant, as it will wash the gold through before it has time to settle. The zig-zag design has the advantage of slowing down the water each time it drops into the next box below. With a I" per foot incline, or a 4" drop for each four foot length of box, you set your pump so that the water flowing through the sluice boxes is not more than about 2" deep over the riffles. You then have a flow rate close to the natural gravity flow of water flowing down that slope. Of course, you will learn to set your boxes at sleeper or shallower angles, depending on the kind of ground you are working. If panning the ground indicates a higher gold content than you are actually getting from your sluice, you'd better check your water feed rate and box angles, and perhaps ease upon one or both of them until you find the right combination,

b. Cleaning Up

After you've been going for several hours, you may want to clean up your box. First, remove the riffles and screen carefully, rinsing them gently into the box. Next, carefully roll up the blanket, starting at the bottom, place it endwise into a pail and wash it off with the hose, so that all the materials trapped on it are washed into the pail. Now replace the blanket, screen and riffles and you are ready to continue washing your ground.

Now carefully pour off the water in the pail, keeping only the solid materials in the bottom. From now on, you follow the instructions in Chapter 6, 'How To Use A Gold Pan', only the materials you are starting out with are much finer. You pan them out in the same way, until you haven few ounces, mostly black sand and gold, left in your pan. Save these in a bottle or other container, and continue panning the rest of the fines you have in the bucket. When you've panned them out as well as you can, the next step is to dry them in a pie plate or similar container, either on the stove, or by setting it out in the hot sun.

A Magnet Gets Rid Of Black Sand

Once the fines are dried, you can stir them around with your finger to find any larger flakes, which can be removed with tweezers. This is where a good, strong horseshoe magnet comes in handy. You can place the magnet inside a glass bottle or an aluminum container.

Either one should be deeper than the magnet. Drill a hole in the lid of the container big enough to pass a piece of strong wire, which is wrapped around the top of the magnet and passes out through the hole to form a loop. With the magnet sitting on the bottom of the container, you pass it back and forth above the black sands without actually touching them, until the magnet is loaded with black sand. Then you hold the magnet container above a clean sheet of paper and pull upon the wire loop. All of the black sand will drop off onto the sheet, and you go back to picking up more, sweeping gently back and forth above it until you've picked it all up. You will now be left with a small amount of non-magnetic materials, consisting of gold, its associates, heavier minerals, and a surplus of fine silts left by the magnetite. While using the magnet, check to make sure you aren't picking up any of the very fine gold along with the magnetite sand. You may lose a very little gold this way, but with care, the problem can be avoided.

Depending upon how impatient you are, and how fine or coarse your gold is, you can now remove all of the extraneous material using a blowing box, or by amalgamation with mercury.

The Blowing Box

The blowing box is a shallow box made often or heavy copper. It is about eight inches long, four inches wide at one end and two inches wide at the other. The sides and long end are at right angles to the bottom and about one-inch high. The narrow end is left open. You place a quantity of the fines in the box, hold it level, and blow in from the side at the wide end, blowing gently across the fines toward the narrow end. At the same time, you shake it slightly from side to side while tapping it gently with your finger. As you continue to blow gently, the fines move up the box and out of the narrow end. A surprisingly clean job is done of removing the lighter sands, leaving the gold behind. With a little practice, you can get quite good at cleaning your fines this way.

![[Most Recent Quotes from www.kitco.com]](http://kitconet.com/images/quotes_7a.gif)